Ramaraj Boopathy, biology professor, has successfully conducted research producing ethanol from biomass like sugarcane waste products, gamagrass and switchgrass, which can be used as an alternative fuel source.

Ethanol, often known for its use in alcoholic beverages, can also be used as an alternative fuel source.

With the aid of a $1 million grant from the U.S. Department of Energy, Boopathy’s research goal is to make cellulosic ethanol, maintained from sugars in sugarcane waste, gamagrass and switchgrass practical and competitive with corn ethanol.

Ethanol is primarily produced from the starch sugars in corn kernels. Boopathy explained that corn has other uses, which is why it is not an acceptable source for fuel.

“Corn is a main food crop. That is why the corn price is going up,” he said. “So what we are suggesting is to not use the food crop, use the residue and the waste product to make ethanol.”

Boopathy explained that it does not make sense to plant corn for the sole purpose of making ethanol. Gasoline is often used to harvest the corn, which is counterproductive.

When sugarcane is harvested, only the stalks of the sugarcane are needed. The waste product, including leaves and grass, are burned in the fields.

“We have used this waste as a resource and we have converted it to ethanol,” Boopathy said. “Right now, we are trying to cut the cost of production, and then we will run a pilot scale plan to demonstrate the effectiveness. After that, it can be commercialized.”

Boopathy said the project is still in the experimental stage. It will take another four to five years before it can be commercialized because production costs are so high.

David Samaha, biology junior from Houma and Boopathy’s lab assistant, said the lab has worked with different biomasses including energy cane, byproducts from sugarcane like bagasse and most recently with gamagrass and switchgrass.

“Gamagrass and switchgrass are not used for agricultural purposes,” Boopathy said. “They grow in the wetlands and pretty much anywhere, like a weed.”

The benefits of using gamagrass and switchgrass are that it is inexpensive, abundant and renewable. These grasses can survive in most soil and can endure extended periods of flooding.

“It’s basically junk grass that grows in fields,” Samaha said. “It is native to south Louisiana, which is why we like it.”

Samples of the gamagrass were collected from the Nicholls farm and stored in the lab.

“The big difference is that with corn ethanol production you are converting starch sugars, but the ones we use are cellulosic sugars,” Samaha said. “Cellulosic sugars are basically unusable, but it is also a more complicated molecule.”

The molecule has to be broken down into three complex chemicals called hemicellulose, cellulose and lignin.

“You pre-treat the organism so it can be fermented, then you add microorganisms to enhance growth,” Samaha said.

Lignin is removed with acid, leaving cellulose and hemicellulose. These two compounds are then broken down with enzymes to make glucose and xylose, the starting sugars for fermentation to make ethanol.

“The sugars are converted during fermentation using a genetically modified strain of the bacteria E.coli,” Samaha said.

During fermentation, samples are collected every three days for a total of nine days to check for ethanol concentration. The ethanol production usually peaks on day six.

The production rate is measured by a machine in the lab called the Gas Chromatography. The GC measures the concentration of ethanol in parts per million, which is then converted to grams per liter.

This semester, three enzymes have been added to boost ethanol yield. These enzymes make more sugars available for the bacteria to ferment.

“This semester the goal is to pinpoint the best amount of each element to make the project cost effective,” Samaha said. “We are hoping it is cheaper and competitive.”

A trial was conducted with the enzymes cellulase, B-glucanase and xylanase each separately, and then combined. The three enzymes combined produced the most ethanol.

An overall benefit of biomass energy, or using plant energy for fuel, is that it is carbon neutral. When oil is burned, CO2 is released and becomes greenhouse gas, which is harmful to the environment and ozone layer. When energy is taken from plants the ethanol burned releases CO2 and the plants grow and neutralize the CO2.

“It becomes a cycle of CO2 production and removal,” Boopathy said.

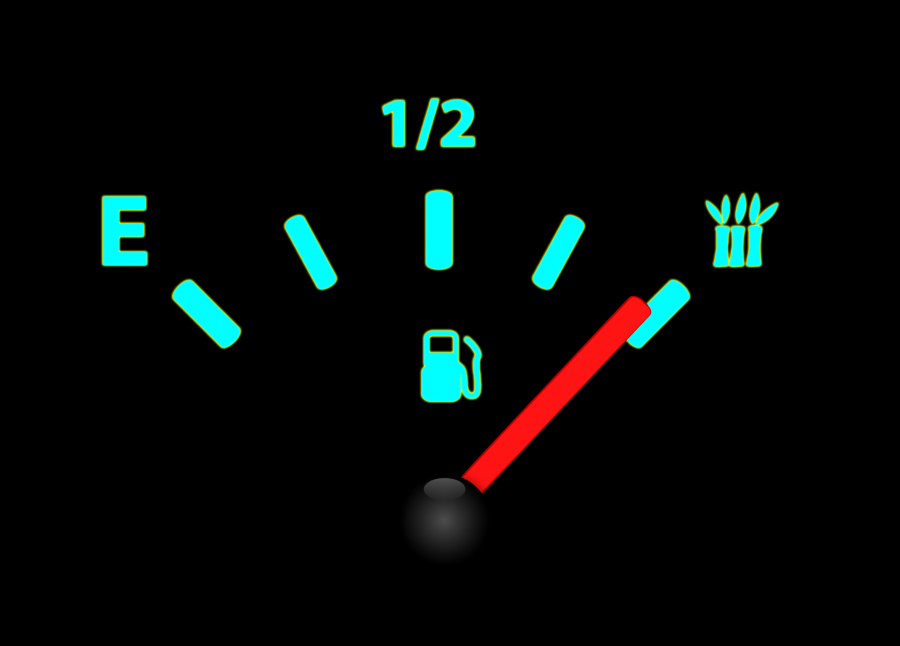

According to the U.S. Department of Energy, the gasoline used in standard vehicles is a blend of approximately 10 percent ethanol and 90 percent gasoline. The use of ethanol as alternative fuel for vehicles reduces the emission of environmentally harmful pollutants.

Caleb Dupre, biology senior from Houma and Boopathy’s lab assistant, said that the research is important because the impact will directly affect the environment.

“We are making fuel that is environmentally friendly,” Dupre said.

Flexible-fuel vehicle models, also known as FFVs, are fueled alternatively with up to 85 percent ethanol and only 15 percent gasoline. There are currently more than 8 million FFVs being used in the United States.

“Right now, corn is being used because it has been commercialized and is being produced large-scale in the Midwest,” Boopathy said. “We are making something like 7 billion gallons for transportation purposes with corn and there are corn farmers who are producing corn solely for ethanol. It cannot be shut down overnight.”

The government is currently subsidizing corn ethanol production, which makes it cheaper.

Boopathy said that production of ethanol from sugarcane currently costs approximately $13 a gallon.

“The government needs to see results first, and then they will subsidize production,” Boopathy said.

If the government subsidizes production of sugarcane ethanol, the fuel will be competitive and could bring costs down to about $2 to $3 a gallon.

“We are running out of oil,” Boopathy said. “Eventually we will run out. It is a finite resource. The biomass is renewable, and carbon neutral.”

John Doucet, head of the Department of Biological Sciences, believes that Boopathy’s research is extremely beneficial in all aspects.

“Dr.Boopathy’s research is contributing to the understanding of the utilization of the natural resources of not only this nation but the world,” Doucet said. “This is a significant achievement coming from a small university like Nicholls.”

Debra Benoit, director of Research and Sponsored Programs, said that Boopathy’s research has been funded by grants from the American Sugarcane League and the U.S. Department of Energy.

“Most of his funds do come from the Department of Energy, but he has also had smaller sources like money from British Petroleum,” Benoit said. “It is all the same work, he just does different segments of the work depending on the funds he is given and what they allow for.”

The U.S. Department of Energy grant will end in December 2012. Boopathy said he is writing another proposal showing the benefits of the research to request another grant.

Dupre said that working in the lab has been an educational experience because the lab assistants do a lot of the hand-on research.

“David [Samaha] and I do a lot of the dirty work,” Dupre said.

Samaha said that working on the research with Boopathy has b

een a good experience.

“Most undergraduate students don’t have the opportunity to work in a research setting,” Samaha said. “It is usually reserved for graduate students, but at Nicholls we are small enough to do it.”